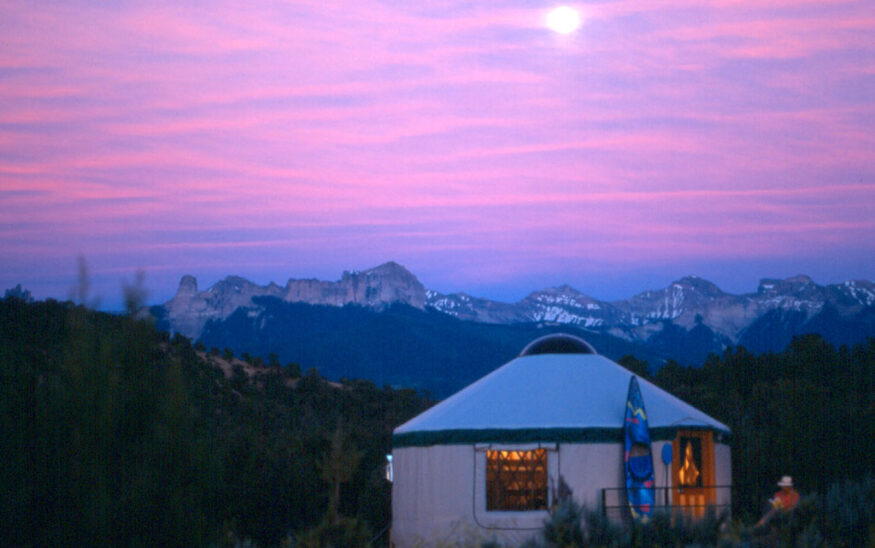

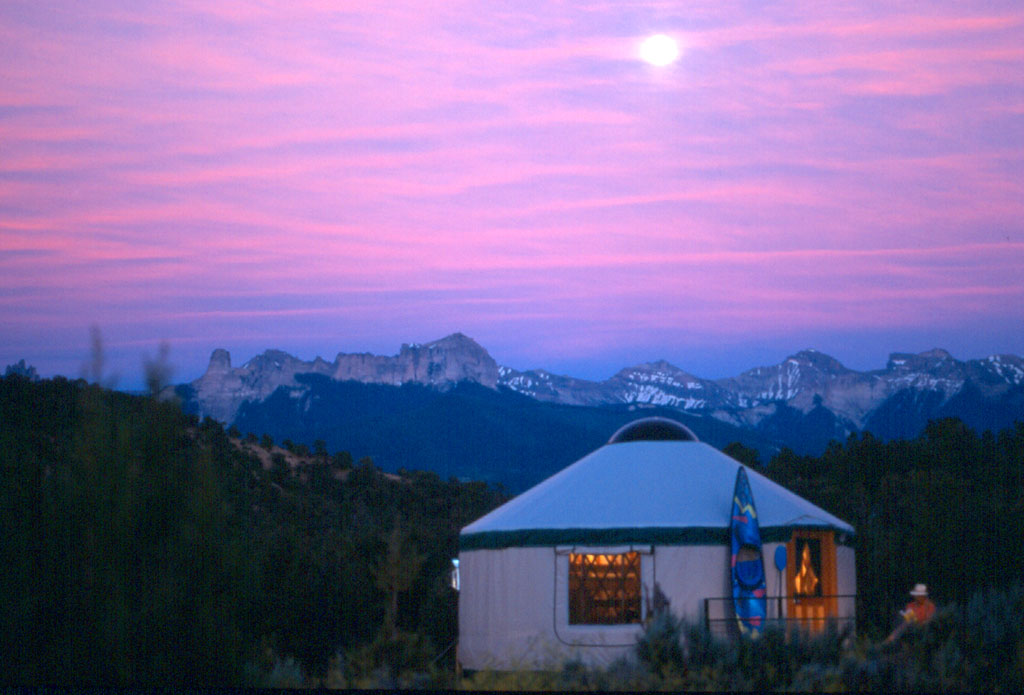

Colorado Companies to Watch Class of 2009: Colorado Yurt Co.

Lisa Ryckman //June 28, 2013//

Dan and Emma Kigar’s first home evolved to become their first business.

Dan and Emma Kigar’s first home evolved to become their first business.

A tipi set up at 11,000 feet in Breckenridge in 1976 grew into Earthworks Tipis, which morphed into Colorado Yurt Co. What started as a home-grown, two-person venture has grown into a 30-person operation with production facilities in Montrose that create everything from 12-foot diameter tipis, tents up to 700 square feet and yurts 30 feet in diameter, all of which meet stringent structural parameters.

Since its inclusion in the inaugural Colorado Companies to Watch class in 2009, Colorado Yurt Co. has posted 10 percent per annum growth and increased its payroll by 23 percent, founder Dan Kigar says. And that’s not all.

“Our company culture has become more transparent and responsive to the creativity inherent in the people who make our organization run,” he says. “Our efforts in sustainability have become more comprehensive and measurable, and we’ve burnished our reputation for innovation, quality and professionalism.”

This year Colorado Yurt’s production department came up with a plan to increase output by 25 percent, and its marketing department developed a corresponding plan to increase sales.

“This potential growth challenged all phases of our company to develop more efficient and sophisticated systems and planning tools,” Kigar says. “Sustaining this growth means hiring more employees and making capital improvements.”

Kigar says being selected as a Colorado Company to Watch was a national marketing opportunity that the company used to lasting advantage. Colorado Yurt’s products were recently featured in a 1,000-item list on the Science Channel’s “How It’s Made,” which took viewers from the company’s design and construction process to the formation of structures on Mount Sneffels.

Kigar says product innovation based on customers’ needs and suggestions plays an important role in helping the company maintain its edge in the marketplace.

“To survive in a locally based manufacturing business, you have to be able to react quickly and intelligently to external pressures,” he says.

The key: People.

“Talented, dedicated individuals make this operation run. And while talent is never in short supply, assembling a team that is willing to pull together has made all the difference,” Kigar says. “Everyone counts.”