Revisiting Recycling – The New School

Part two: How Colorado is experiencing shifts in the recycling industry

Bryce Isaacson //January 16, 2019//

Revisiting Recycling – The New School

Part two: How Colorado is experiencing shifts in the recycling industry

Bryce Isaacson //January 16, 2019//

In part one of this series, we discussed the evolving recycling industry and the factors behind China’s new recycling specifications. Here, we highlight how these changes have impacted recycling locally in Colorado, as well as nationally and how we can overcome the new challenges.

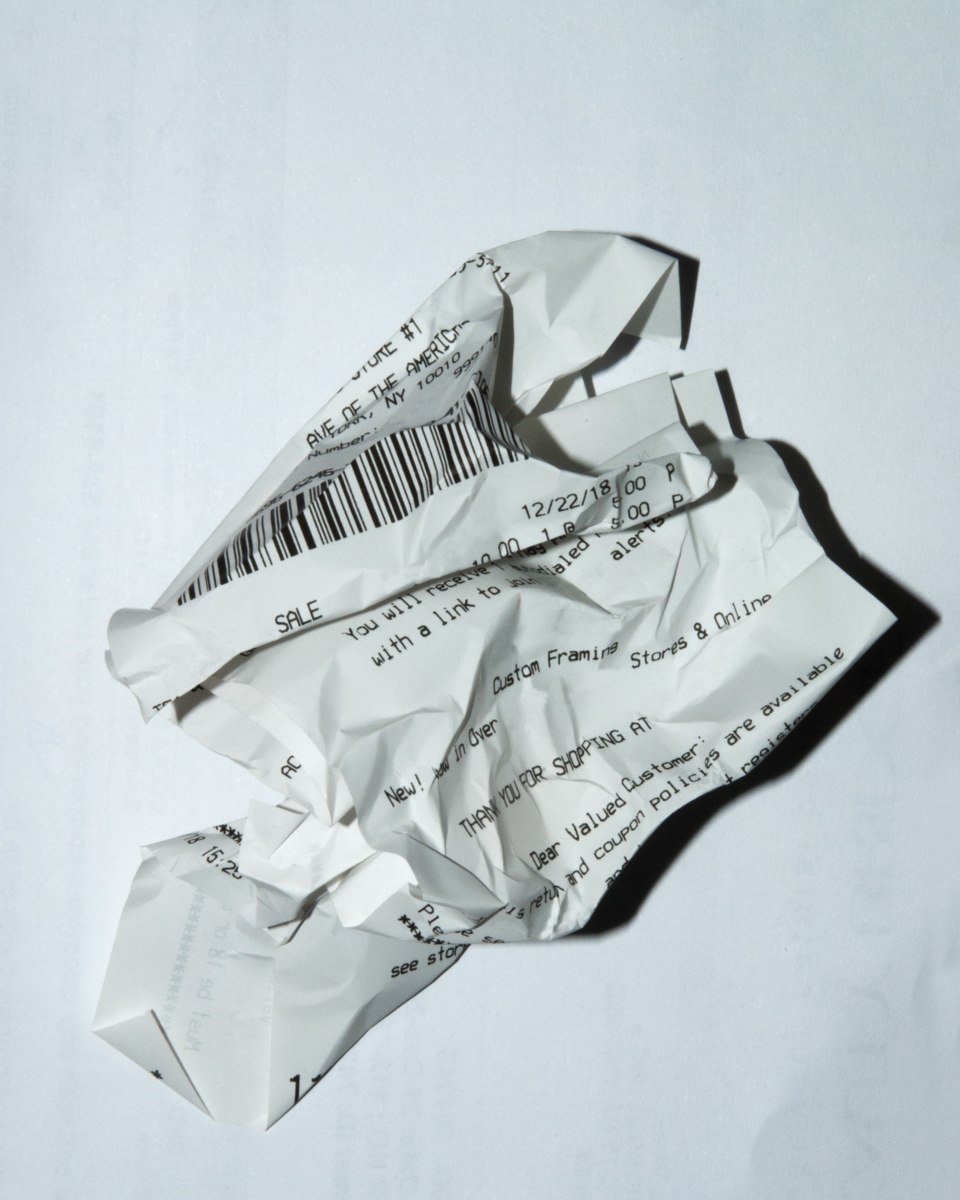

Current recycling market gloominess has been caused by Chinese and other Asian nations' establishment of new specifications and quotas for imported recyclables, having a tremendous impact on the recycling industry, both nationally and locally.

NATIONAL IMPACT

- HIGHER PROCESSING COSTS TO MEET NEW QUALITY STANDARDS

Material recovery facilities (MRFs) must slow down their sorting lines and add more sorters to manually remove more contaminants from the material stream, lowering efficiency and increasing processing costs. - HIGHER TIPPING FEES CHARGED + LOWEr REBATES PAID FOR SOURCE-SEPARATED MATERIALS PROCESSING FACILITIES (MRFs)

A tipping fee, sometimes called a gate fee, is the charge to bring in a given quantity of waste at a processing facility, typically levied by the ton. In many markets, the tipping fee for single-stream recyclables drop-off is now higher than the area’s landfill tipping fees. - LOWER REVENUES FROM THE SALE OF MATERIALS DUE TO DEPRESSED COMMODITY PRICES

The loss of our export market to China has led to less demand and oversupply, which has led to lower revenues on some materials, negative pricing on others and overall lower revenue to single-stream processing facilities. - INCREASE IN MONTHLY RECYCLE COLLECTION FEES TO BOTH COMMERCIAL + RESIDENTIAL CUSTOMERS

When collection programs, both private and public, must pay more and/or receive less to have their recyclable materials processed, these costs are passed onto consumers and businesses in the form of higher collection rates and/or lower rebates. - HIGHER CAPITAL IMPROVEMENT COSTS

To meet the new higher quality standards, some MRF owners and operators must install more costly sorting equipment, such as optical sorters or robotic sorters, to make their materials marketable. - UNAVAILABILITY OF MARKETS + STORAGE

The inability of our domestic market and other foreign markets to absorb the materials we previously sold to China has disrupted our supply chain. For facilities without storage capacity, there is no choice but to landfill materials that have no market. To put the storage issue into perspective, the U.S. throws away 2.5 million plastic bottles every hour – about 42,000 per minute, or about 695 per second. Add in paper, aluminum, cardboard, glass and other recoverable items, and the sheer volume of the storage problem becomes clear.

LOCAL IMPACT

While Colorado (perhaps surprisingly) hasn’t been the greatest recycler, new restrictions imposed by China on contamination levels, mixed paper and plastics aren’t making things any easier. To date, there have not been any changes to programs across the state. For example, both Boulder County and the county’s recycle center operator, Eco-Cycle, have done a great job of processing and marketing local materials during this time of transition.

Eco-Cycle has been able to find markets for all materials even when others have not. The facility model does not produce a mixed paper product, but rather a sorted office paper product, which still has a strong market value. Additionally, they have not been plagued with the revenue loss or lack of market for paper that some other facilities have. Thanks to the efforts of local residents and businesses, the Boulder County Recycle Center boasts a contamination rate of less than 10 percent — or less than half the national average of 20 to 25 percent. Boulder County and other local Colorado communities are also fortunate to have Momentum Recycling located in Broomfield to process the glass fines from the state’s materials recovery facilities and Rocky Mountain Bottling in Golden to buy the glass cullet and bottles created for the manufacturing of new bottles. Many other markets and areas of the country do not have the advantage Colorado does for its glass.

Consumers in the United States, largely unaware of new regulations and developments, expect the materials they put in the recycle carts be recycled and have come to expect the service should be free. In fact, many consumers believe their recyclables are worth a lot of money, so any fees charged can feel unfair. The entire industry must work together to institute many necessary changes, including:

- INVESTMENT IN DOMESTIC MANUFACTURING INFRASTRUCTURE THAT CAN USE OUR RECYCLE PLASTIC, FIBER MATERIALS + SCRAP METAL

We need to become self-sufficient and not rely on the rest of the world to take our discards. - DEVELOPMENT OF NEW DOMESTIC MARKETS FOR OUR MATERIALS

Developing new markets will increase the value of materials and help change the new economics of recycling. - INCREASING EDUCATION AT ALL LEVELS SO MATERIALS DELIVERED TO OUR MATERIAL RECOVERY FACILITIES (MRFs) ARE AS FREE OF CONTAMINANTS AS POSSIBLE.

Focus our efforts to reduce contamination on the core recyclable materials and not add new materials that don’t have developed markets. Diversion does not equal recycling. - MAKING SURE WE ARE PRODUCING HIGH-QUALITY RECYCLABLES FROM OUR MATERIAL RECOVERY FACILITIES (MRFS).

In doing so, the recyclable materials are desired by both domestic and international markets. - COMMUNICATING WITH OUR GENERATORS, CUSTOMERS (BOTH COMMERICAL + RESIDENTIAL) + OUR RECYCLING PARTNERS WITH TRANSPARENCY ABOUT THE ECONOMIC REALITIES + WHY THEIR ACTIONS + SUPPORT ARE SO IMPORTANT.

This is an industry-wide and worldwide issue, not just a local problem. Everyone is now feeling the pain of the new recycling economy, so everyone must work together to meet the challenges.

As recycled plastics, glass and mixed paper continue piling up at many recycling plants across the country and where they can’t make a profit by processing them for export or domestic markets, the ripples of China’s decision are being felt around the state and the country. While the global challenges the recycling industry is facing these days are without precedent, we all have a role to play in making recycling sustainable for the future.

Bryce Isaacson is vice president of Sales and Marketing for Western Disposal Services, Boulder County’s largest full-service waste management company for trash, recycling and compostable materials.